This year we have implemented several production efficiencies to focus our efforts on sustainable farming. Three production efficiencies to remain sustainable on farm include water usage, energy consumption, and reducing waste. As an outcome of COVID-19, we re-evaluated many of our production Standard Operating Procedures (SOP’s) and determined ways to reduce cost at the sow farm, while maintaining performance. Through a combination of research and observation on farms, here are the big 3 from 2020:

Increase energy efficiency: heat mats

Our new farms and several renovated farms have installed the Innovative Heating Technologies Hog Hearth heat mat. “Our clients are finding an energy savings of $0.40/weaned pig in crates using the Hog Hearth heat mat when compared to using a crate with heat lamps and rubber mats,” says Chris Grant, President IHT. “All pieces of the mat are 100% recyclable, should the mat ever become damaged and need to be disposed”. In addition to large energy savings, we have seen reduced labor and water needed to power wash the heat mats, and a greater area of heated floor space for the piglets to lay on. All of these benefits have been observed, with no change to sow or pig performance, indicating increased energy efficiency in our farms.

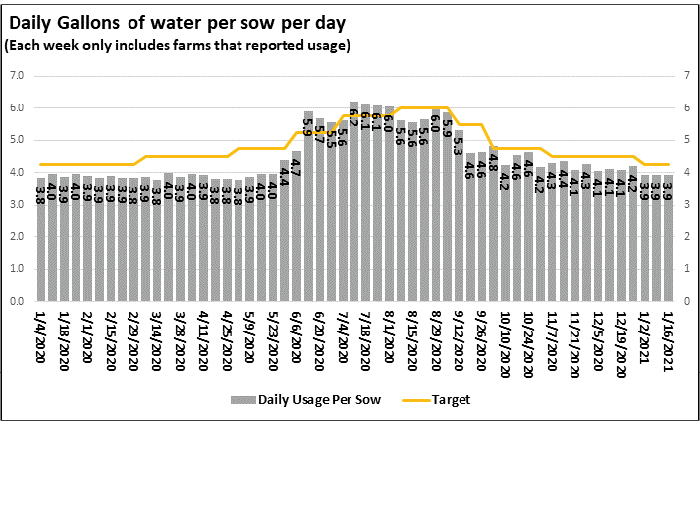

Decrease water use

You can’t improve what you don’t measure. Over the past year we have placed emphasis on collecting weekly water usage (gallons/sow/day) across our managed sow farms. As seen in the graph to the left, water usage increases during the summer months and stays relatively flat during the remainder of the year. We are now looking at opportunities in daily practices at the farm to reduce excess water usage, and do our part to improve sustainability on our farms. As mentioned above, we have found the heat mat material was easier to clean than the previously used rubber mats, which helped to reduce water.

Reducing our impact on the landfill: Heat lamp bulbs

Everyone knows how easy it is for a heat lamp bulb to shatter, whether it is from a piglet jumping up or a worker accidentally knocking the lamp. Changing heat lamp bulbs takes time, money, and contributes to waste produced by the farm over the year. Recently, PIPESTONE has adopted the use of infrared heat lamp bulbs. The infrared bulbs are both more durable, (you can knock the lamp on the side of the crate and it won’t break), and do not burn out as quickly. We measured bulb usage at a sow farm managed by Pipestone Management before and after converting the infrared bulbs and found almost a 5x decrease in bulb usage. This simple change has allowed the farm to save money on lamps, time changing bulbs and allowing staff to spend more time attending litters.

What are production efficiencies can you implement on your farm, or would like to see us evaluate at Pipestone Management? Together we can help farmers today create the sustainable farms of tomorrow.

By: Kiah Gourley, PhD Nutritionist and Sow Technical Service