One distinct memory I have growing up was riding along with my Dad (before car seats) in the feed truck when he worked as a delivery driver and ultimately feed salesman for Wayne Feeds in Ireton, IA. He would stop at a gas station and let me pick out a jelly-filled long john or a king sized Snickers. Neither of which were on the “approved-by” list of my mother. Dad was delivering what I can only assume was “concentrate” to some of the local farmers who had vertical mixers not so different then the one we used at home to feed sows.

As with all things, the technology advanced and operations outgrew the vertical mixers. Basemixes followed and ultimately VTM based diets were made at the local elevator instead of at home. However, there were and are a few farmers and integrators alike that saw the opportunity to erect their own feedmills and utilize the corn they grew or could buy from local farmers. So, how can it be that today some farmers grind feed at their own feed mills while others purchase feed from local toll mills? Is one wrong and the other right? See below for a short and non-encompassing pros and cons list.

Own Your Feed Mill Pros & Cons

Pros

- Ingredients sold at “cost” no margin

- Control of where ingredients come from (quality)

- Flexibility of design, delivery timing, etc

Cons

- Requires sold at “cost” no margin

- Requires expertise to operate/procure

- High labor and time required to operate

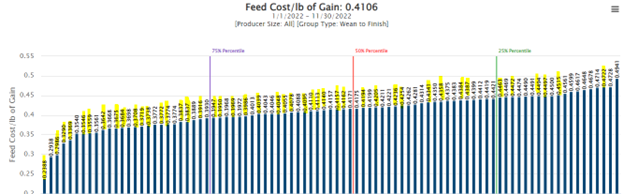

Ultimately the farmer has a choice to make on whether they can manage the asset and skillset required to own and operate a feed mill. When we look specifically at on farm mills compared to toll mills and what that means for Feed Cost/lb of gain we can piece some of that out from our benchmark data. In the below chart you can see that the majority of producers with the best Feed Cost/lb of Gain have on farm feed mills (highlighted). I think important to note that having an on-farm feed mill is not a guarantee of being a low cost producer and outside factors like pig health, nutrition, and management all can and at times do have superseding effects on the cost of gain.

As we have studied this over the years it has become apparent that owning a feed mill in all generality has been beneficial for those that invested the equity on such a project. To compliment this, Pipestone Nutrition has begun a new service offering for feed mill management. Which is aimed at allowing farmers to own the Feedmill without some of the headaches (labor, time, expertise) of operating them while also allowing for some efficiencies of scale to own the facility with other producers. They are very similar to a managed sow farm where the sows and real estate are owned by the farmers and Pipestone provides the management. This model, though in its infancy, does appear to have similar benefits from a cost savings perspective to the end user. It also allows smaller farmers that don’t have the expertise, labor, time to operate and own their own mill to work together with other producers in a larger, more efficient mill that’s operated and managed by an outside entity (Pipestone).

For farmers to continue to be competitive we believe they will need to continue to own and control the assets from the land – sows – barns – feed mills – harvest facility – retail chain. Whether you can do this on your own, with a partner or an outside expertise, then becomes the decision. Though a managed feed mill may not be the right choice for all, I do think it’s an option for those willing to, and able to invest further into the value chain.